Engineering Technologies Canada Ltd. (ETC) was retained by Hartshire Holdings to design a state-of-the-art, cost effective and green onsite sewage system for the Burnside Community Care Home in Clyde River, PEI.

in Clyde River, PEI

The new 40 bed community care home features both single and double-bed rooms. The building has three levels, wheelchair accessible showers, dining room, community room, a chapel, beauty salon, activity room and two lounges. The beautifully landscaped grounds will feature a courtyard, screened-in deck, veranda, walking trail and a garden.

Onsite Challenge

However, being located in a rural area meant that the facility could not simply be connected to a city sewer system; it would need to have its own onsite sewage treatment system. Alan MacPhee was initially “hopeful but a little bit concerned about that”. Then he got some disappointing news – “The first engineering opinion we got was quite discouraging” says MacPhee. “We were told that the (soil) conditions were not suitable and that was the end of the story”. Concerned, but still hopeful, MacPhee wasn’t prepared yet to give up on his dream to build on the beautiful rural site.

A Second Opinion

Two contractors suggested MacPhee contact Kelly Galloway for a second opinion. They knew that ETC specialized in rural wastewater management challenges and may be able to come up with a solution. MacPhee did just that. ETC Principal Engineer Kelly Galloway, P.Eng. started by carrying out a careful assessment of the subsurface soil, rock and groundwater conditions. Upon completion of this assessment, she was confident ETC could design a solution to meet technical, environmental, regulatory and financial objectives. ETC looked into various sewage treatment and effluent dispersal options which would be appropriate for this type of facility. Both conventional septic, and advanced sewage treatment (that would purify the wastewater to a much higher degree) were considered. It was also important that the selected system would be cost effective to install and operate.

Advanced Treatment System

After presenting the results of ETC’s feasibility study of various options and costs, MacPhee took ETC’s advice and decided to proceed with an advanced sewage treatment system, instead of a conventional septic drainfield.

Advanced secondary sewage treatment is carried out using the Advantex treatment system manufactured by Orenco Systems Inc., and distributed locally by Atlantic Purification Systems, Dartmouth, NS.

Land Dispersal

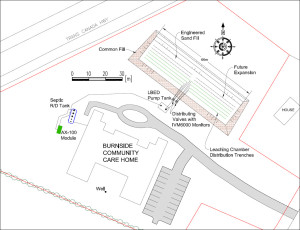

Land-based dispersal of the highly treated effluent is achieved using a pressurized, Infiltrator leaching chamber dispersal field constructed in a raised-bed of special sand fill.

Kelly Galloway explains: “The soil conditions at this site consist of compact glacial till soil – fine sandy loam, which does not have good vertical permeability. These conditions are very typical of many areas of PEI and the Maritime provinces. As a result, it was necessary to bring in good quality sand fill to build up the dispersal field for the treated effluent. The contractor had to search to find the right sand to meet our specs, but this was important to achieve the long term performance that the Client requires.”

Remote Monitoring and Reliability

The dispersal field bed was designed with multiple zones or cells, each zone being fed via a mechanical indexing valve. This approach allows much smaller, lightweight, and inexpensive pumps to be used, and also simplifies future expansion. If additional dispersal zones are ever needed, minimal changes would be needed to the distribution system design. For enhanced reliability, the mechanical distributing valves are fitted with IVM6000-LP electronic monitors. Also, the entire sewage system can be remotely monitored.

Successful Solution

The system has been in operation for over a year. “At the end of the day, we have what we feel is a green and a well functioning system”, says MacPhee. “Kelly and her staff were very personable, and very professional to deal with. So for us, it was a very successful project”.

Ms. Galloway notes “The sewage system is essentially a smaller scale version of the national award winning system ETC designed for the Village of Victoria, PEI. It was a privilege to be entrusted with this challenging design by Mr. MacPhee. We also credit the success of the project to the professionalism of Island Coastal Services and septic subcontractor Philip Clark. The attention to detail shown by Atlantic Purification Systems was also much appreciated.”

For more information about accommodations at the Burnside Community Care Home, visit their web site.

For more information on how ETC can provide innovative wastewater management solutions for your next project, contact Kelly Galloway, P.Eng. via email (kelly@engtech.ca), or Toll Free at 1-888-747-7645 (SOIL).